Business & Home

Slash Your Energy Bills Using

Power flush UK

Through our advanced central heating system improvements, we guarantee less energy usage, major savings, and a generous 5-year warranty period.

Are you looking to Warm Up Faster or Pay Less In The Business or At Home?

Business Power flush

OVER 97%

Of Customers See An ROI

In the first month on Energy Bills

Home Power flush

UP TO 14X

Efficiency Improvement

Compared to other providers

Try 100% free quote. No Obligation

Try 100% free quote. No Obligation

Does My

System Need A Powerflush?

Knowing whether you need a power flush for your heating system can save you from potential costly repairs in the future. Here are some common signs that suggest you might require a power flush:

If you observe any of the above signs, it's a good idea to consult with our team of heating circulation specialists.

Try 100% free quote. No Obligation

Our Solutions For Your Home & Business

Explore What Is A Power Flush

in just 2 minutes!

A power flush refers to a process used to clean and maintain the central heating system. Over time, radiators and heating systems can become clogged with sludge, rust, and other debris, which can reduce the efficiency of the system and lead to other problems.

Try 100% free quote. No Obligation

How

Does Power Flushing Work?

Power Flush UK specialises in revitalising heating systems, using a meticulous four-step process to diagnose, treat, and thoroughly cleanse systems of obstructions and inefficiencies. With our professional approach, we guarantee optimal heating performance, providing customers with both a certificate of cleanliness and a 5-year blockage-free assurance.

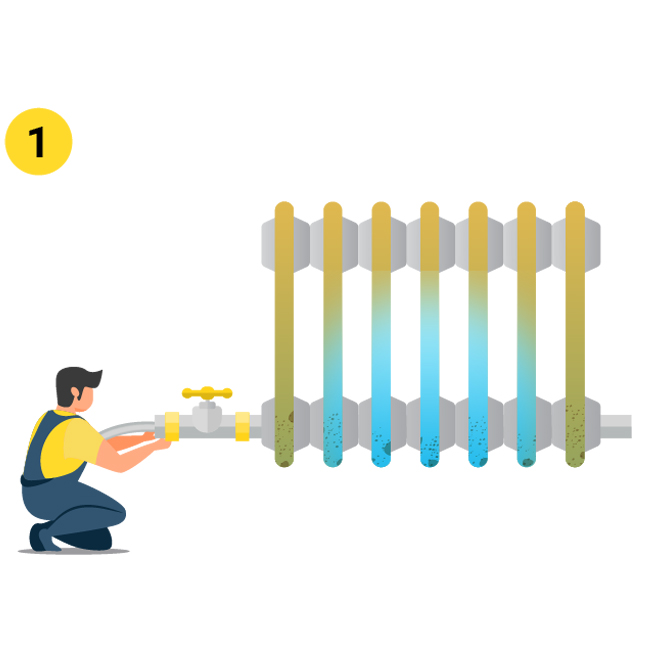

Connection

Stage

A heating engineer will connect a high flow and low pressure pump to the heating system

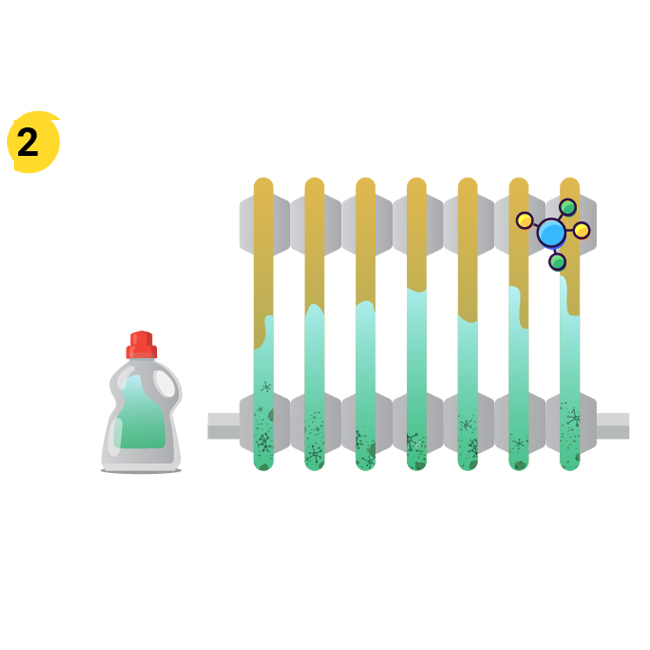

Chemical Cleaning

Cleaning chemicals containing sludge breaking enzymes and often a de-scaler are added to flush out any debris or bacteria present in the system

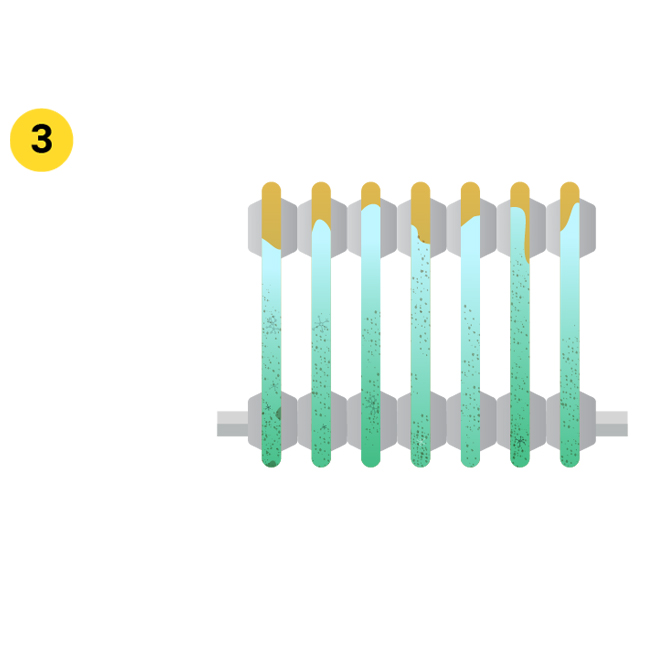

Power

Flush

The chemicals work their way though, breaking down limescale, rust and other debris.

Inhibitor

Added

To ensure no contaminants remain, a clean water flush is performed after the chemical cleaning before adding rust proofing inhibitor.

Certificate

Issued

Water samples before, during and after the process is logged and issued in your certified certificate

Why

Power Flush UK?

Choose Power Flush UK for a thorough, expertly executed heating system revitalisation, ensuring both peak efficiency and a prolonged system lifespan. Benefit from our transparent, competitive pricing and unparalleled guarantees, setting us apart as the top choice in the UK.

Try 100% free quote. No Obligation

5 Year No Blockage Guarantee

Get your system protected with our 5 year promise. Terms and conditions apply.

22 Year Proven Track Record

Join our family of satisfied customers who've experienced significant heating improvements and savings.

Detailed Diagnostics

Receive both visual and written evidence detailing the state of your heating system.

Certified Cleanliness

Obtain an official certificate, a seal of guarantee showcasing the pristine inner condition of your system post-flush.

Convenience and Respect

We schedule around your time and ensure your home remains as immaculate as we found it—only with better heating!

Affordable Excellence

Get top-tier service at a competitive package price - a fraction of what some national suppliers charge!

Expertise You Can Trust

Rely on our trained professionals, committed to providing best-in-class service and lasting results.

Transparent Pricing

No hidden fees or surprise costs—what you see is what you pay.

Eco-Friendly Approach

Benefit from a cleaner system that's not only good for your pocket but also for the environment.

Frequently asked questions

Powerflushing is purely and simply a way of removing the rust that slowly builds up in your heating system and boiler over time. Water, chemicals, powerflush equipment and an experienced plumber are used to remove the rust and sludge from your central heating. The flow of the machine is reversed from time to time using special three-way valves attached to the flushing pump. This is an extra step to help clean the pipes and radiators to remove cold spots.

Yes, we provide a full guarantee. At the end of each job we will post a certificate to you that guarantees your power flush.

No. A power flush can be undertaken by an experienced and knowledgeable engineer as we do not touch the gas supply or exhaust vent system.

The reason that happens is generally one of two things:

1. Your pump has failed or is stuck. The water can’t circulate and therefore the water that is in the heat exchanger will boil very quickly. In some older boilers in particular it takes a while for the thermostat in the boiler to turn the gas off. In modern condensing boilers the thermostats are more sensitive and will extinguish the boiler flame quickly.

2. There is a blockage in the main flow or return pipework, or with the water ways in the boiler heat exchanger which is either completely or partially blocking the flow of water through the boiler – so the water in the boiler starts to boil and make steam again. Hence the popping, hisses and bangs.

If you have seen someone else’s system power flushed you will know what an amazing amount of rust and radiator sludge can come out, in all shapes and sizes. But, contrary to popular belief the vast majority of the sludge that you see does not come from your boiler. Most non-condensing boilers (those installed before 2006) have cast-iron heat exchangers and they, by and large, do not rust. The vast majority or rust and/or sludge in your heating comes from the radiators themselves as they are made from mild-steel.

Water is made of hydrogen and oxygen (one part H and two parts O = H2O). Oxygen is highly reactive and is always looking for somewhere to latch on to instead of the Hydrogen molecule. So, any time it comes across a piece of iron that is ‘bare’, i.e. unprotected, it is going to latch on to that and makes rust (most often Fe2O3). And that’s where rust comes from. Power flushing radiators will remove that.

Once you have had a specialist in to do the work for you, the best way of protecting your system is to have the heating system regularly topped upped with corrosion inhibitor. These stop the rust forming by adding a protective molecule to any exposed bare iron. That molecule (most often a form of another metal called molybdenum) parks in the place that the oxygen molecule would want to be. And the result is no rust. The only caveat to this is if your heating system has a design flaw in it and is pulling in fresh water all the time.

Yes, there are other ways of cleaning your central heating system, but they are nowhere near as effective as using a the right machine when it is used by a competent and experienced heating engineer. You can add any chemical cleaner in to the system, leave for up to four weeks (Warning:careful here if you have micro-bore pipework) and then open up the system drain-cocks and let the water run out.

When you do that the only force moving the water out of the system is gravity and that will not pick up any larger bits of rust. Those will be left in nooks and crannies.

Yes, a power flush can fix cold radiators. Particularly if they are cold at the bottom. Sludge collects in an arc in the bottom of radiators, so if your radiator is cold in the middle or at the bottom it can be a sign that sludge is building up. Other places that sludge commonly builds up are in the airing cupboard and at the manifolds in microbore systems.

The short answer is “Yes, it can”, but with a great deal of care. 10mm microbore systems need to be approached in a very different way to standard sized pipework. 8mm microbore systems need a lot of careful thought before flushing out. Microbore pipework was first commonly introduced in the 1970’s in an attempt to reduce the amount of copper needed to install a heating system.